Stop Replacing. Start Rotating.

Maritech pioneered the Rotation Program: proven by leading fleets to cut downtime, lower costs, and keep vessels always ready. Be ready before the emergency — with specialized rotation packs always on hand.

Cost ↓ | Downtime ↓ | Asset Life ↑ | Environmental Impact ↓

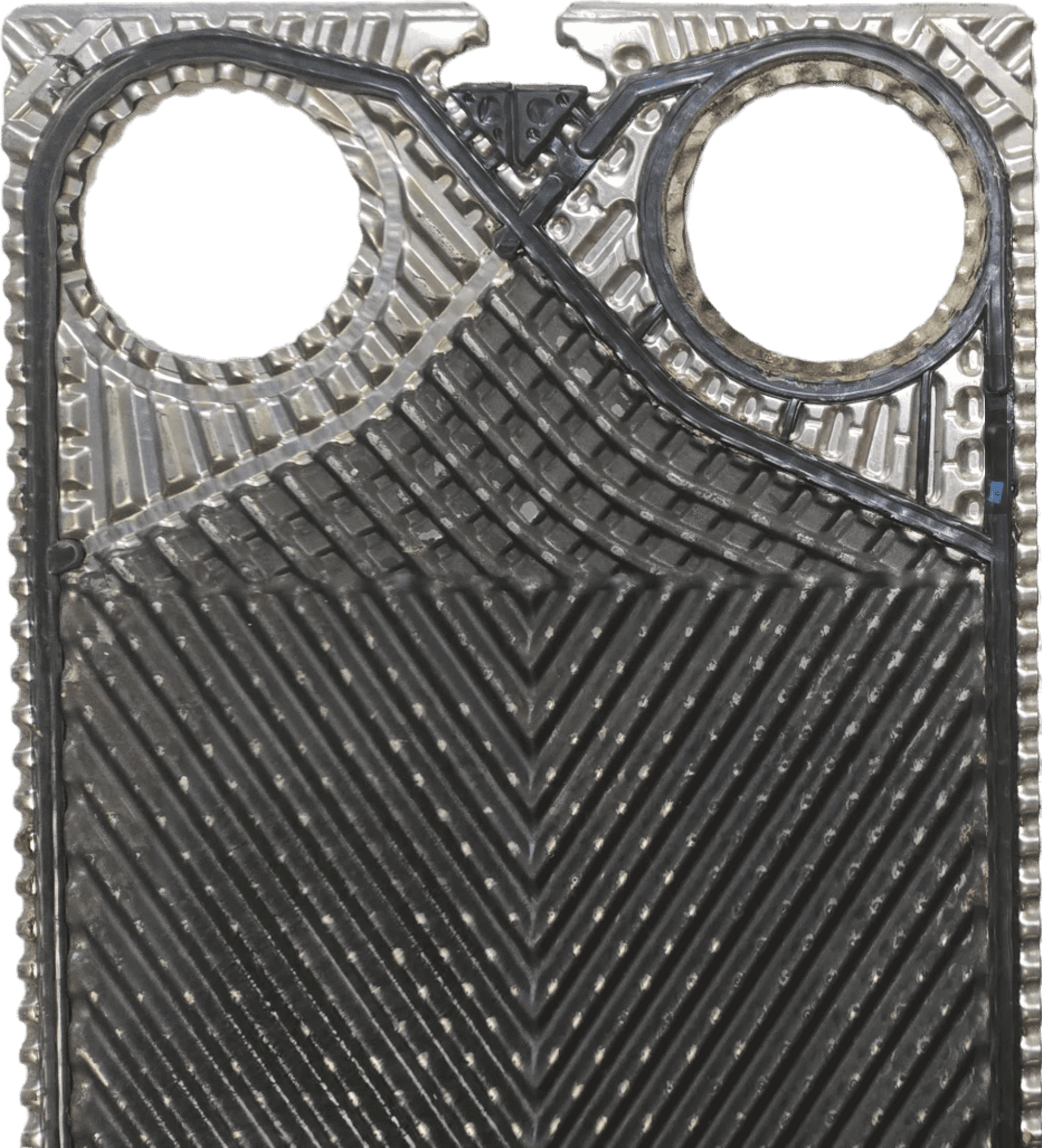

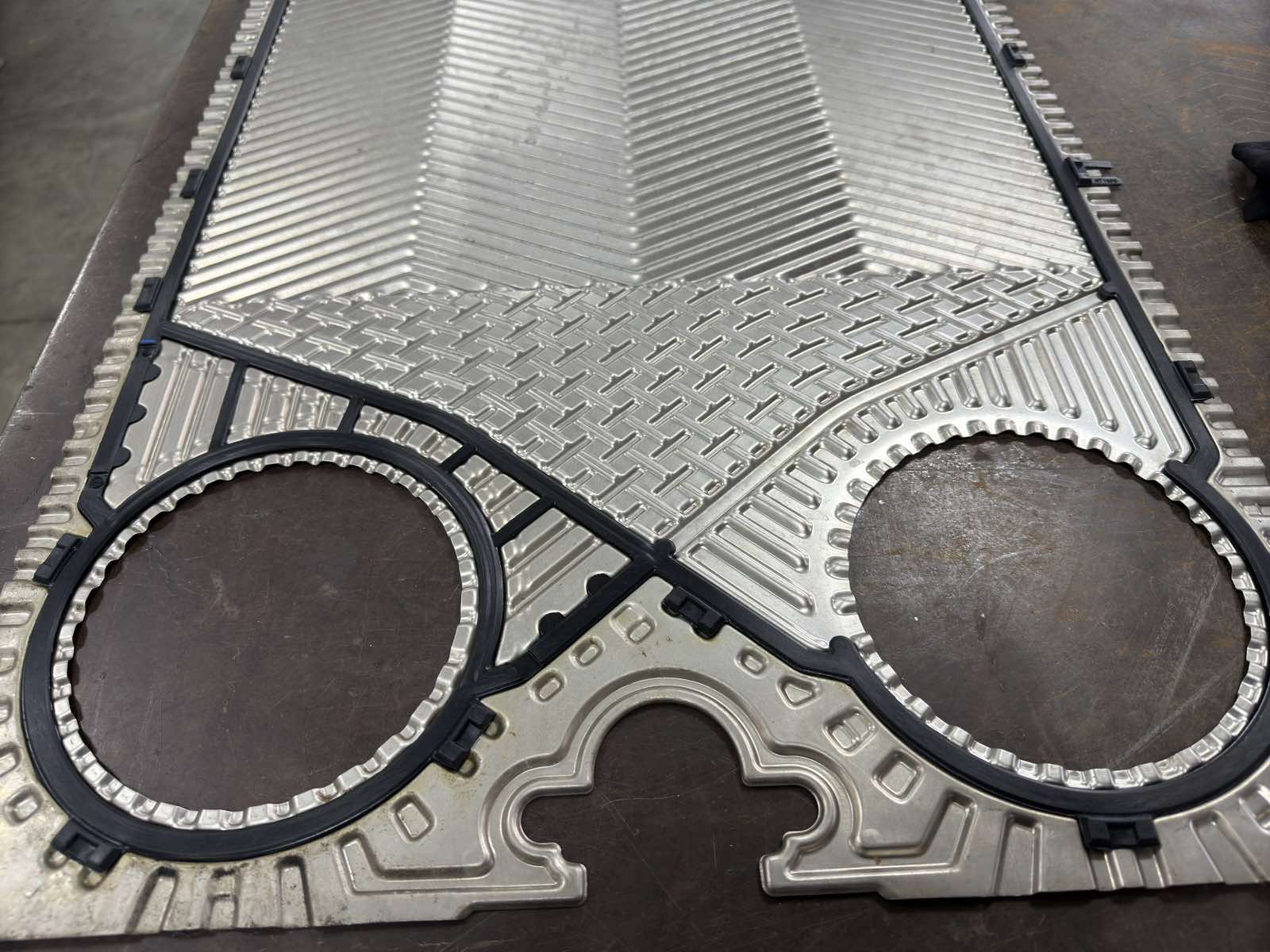

We begin with a thorough inspection to assess plate condition and identify any wear, deformation, or fouling. Our expertise ensures that only plates suitable for refurbishment proceed, protecting your operations from avoidable risks and reducing unnecessary replacement costs.

Using precision cleaning techniques, fouling and deposits are removed without compromising plate surfaces or gasket grooves. This restores optimal flow and thermal efficiency while preserving material life — delivering reliable performance over more cycles.

Each plate undergoes rigorous verification to confirm material integrity, surface condition, and gasket fit. This ensures every unit leaving our facility is ready for safe, efficient operation — giving you confidence, reducing downtime, and extending asset life.

Industries we Support

Services Portfolio

for Uptime & Lifetime

Technical Services

Service Agreements

Manufacturing

as a Service

Case Studies & Projects

The Challenge

An 80K bulk carrier operating in warm-water regions experienced cooling loss on its central cooler.

The unit no longer had sufficient thermal margin, and as seawater temperatures increased, the fresh-water outlet temperature rose beyond safe limits.

The Turning Point

Maritech OceanServ performed a full thermal review and confirmed that the cooling margin was inadequate for the vessel’s current thermal load, which had increased over time (e.g., upgraded generator capacity and higher onboard demand).

• Capacity Upgrade Engineered – To meet the new load, a capacity upgrade was engineered by adding plates while maintaining acceptable pressure drop.

• Full Refurbishment & Commissioning – The cooler was fully refurbished, re-assembled, pressure-tested, and commissioned onboard.

The Result

✅ Cooling efficiency was restored, and the system regained a safe thermal margin even in warm-water conditions.

✅ Performance remained stable.

✅ Service intervals were extended.

✅ The vessel regained operational confidence.

Lessons Learned

Cooling performance issues cannot be resolved by maintenance alone.

When the vessel’s thermal load increases, the cooler’s capacity must be re-engineered to match real operating conditions.

Proper thermal evaluation and targeted upgrades ensure long-term reliability, especially in warm-water environments.

The Challenge

On an Aframax tanker, the fresh-water generator (FWG) was underperforming, forcing the vessel to rely on costly bunkered water and reducing voyage autonomy.

The owner had already ordered replacement parts, but OEM supply-chain delays meant critical components would not arrive in time.

With the vessel under tight charter commitments, downtime or performance loss was not an option — yet continued operation risked efficiency degradation and rising cost.

The Turning Point

Maritech was engaged to restore not only function but performance, identifying and solving the root cause without waiting for delayed spares.

• Performance Assessment – Onboard inspection confirmed reduced production and vacuum instability, pointing to backpressure in the air-brine ejector circuit and heat-transfer imbalance across the plate pack.

• Root Cause Analysis – The air-brine ejector pump showed erosion and excessive wear-ring clearance, reducing suction and vacuum efficiency. Meanwhile, deformed plates and aged gaskets caused internal leakage and loss of sealing integrity — restricting flow, increasing backpressure, and lowering evaporation and condenser efficiency.

• Rapid Parts & Fabrication – Using Maritech’s regional stock and on-demand manufacturing, critical components — including impeller and wear-ring assemblies — were produced and delivered within days. Fully compatible and precision-machined, they replaced delayed items and boosted vacuum and FWG performance.

• On-Site Service – Maritech technicians completed cleaning, plate refurbishment, gasket renewal, and ejector upgrades with improved parts, restoring vacuum stability, correct flow, and full design output.

The Result

✅ Production restored, exceeding pre-incident levels.

✅ Dependence on bunkered water eliminated.

✅ Equipment life extended through refurbishment and selective upgrades.

✅ No off-hire, with warranty-backed assurance.

What began as a supply-chain delay became a performance-recovery success story, driven by Maritech’s technical agility, insight, and integrated logistics.

Lessons Learned

When critical parts aren’t available, agility and root-cause engineering keep vessels operational. By combining diagnostics, regional readiness, and field precision, Maritech turned a supply-chain challenge into a clear operational win.

Strategic Outlook

This case embodies the OCEANSERV® – Preventive Care philosophy: early diagnostics, rapid response, and technical excellence. Beyond repair and supply, Maritech delivers predictable performance, optimized lifecycle cost, and sustainable reliability across shipboard systems worldwide.

© Maritech Group Holding – All rights reserved.

MARITECH OCEANSERV® is a registered trademark of Maritech Group Holding (Hong Kong).

A NEW EQUILIBRIUM IN SHIPPING: THE VISION OF THE MARITECH GROUP

Honoring World Maritime Day 2025, our CEO, Dimitris Sorokas, shares in an in-depth interview with TheTOC news portal. He outlines the company’s vision and strategy as the current challenges in shipping call for collective responsibility while simultaneously opening up significant avenues for innovation and sustainable solutions.

He highlights the MARITECH Green Series, a cutting-edge line that successfully merges technical reliability and cost reduction with crucial marine environmental protection.

Mr. Sorokas also emphasizes that the future belongs to those who combine technical depth with local speed, building partnerships based on trust and technical value to ensure operational continuity in an era of intense change.

Read the original interview (in Greek) from TheToc: here.

The Challenge

During a vessel drydock at a leading shipyard in Turkey, the condition of the cooler’s plate pack was not identified early enough by the assigned contractor. By the time the failure was confirmed, several plates were already damaged — leaving the vessel off-hire and under significant commercial pressure, with daily off-hire losses reaching tens of thousands of dollars.

The Turning Point

Maritech was called in to address the failure, providing technical service on site and supplying the required plate pack renewal from stock.

• Rapid assessment – Our engineers inspected the unit and confirmed the extent of the failure.

• Refurbishment where possible – Components that could still be used were reconditioned: cleaned, re-gasketed, and realigned.

• Stock-backed renewal – Replacement plates were delivered directly from stock, secured through Maritech’s stock network to ensure immediate availability.

• On-site support – The system was reassembled and tested under Maritech supervision, ensuring reliable performance before the vessel’s departure.

The Result

✅ The vessel was able to return to service within only 48 hours, as Maritech teams worked around the clock to restore full operation and minimize further off-hire costs.

✅ By delivering both technical service and reliable spare parts, Maritech proved its ability to support shipyards in keeping projects on schedule — building trust and helping them strengthen relationships with shipowners while avoiding costly delays.

Lessons Learned

This case highlights how late failure identification can escalate costs rapidly. At the same time, it reflects a broader industry reality: shipyards today demand specialized services that go beyond standard docking — solutions that deliver faster turnarounds, predictable costs, and warranty-backed quality. This is exactly where Maritech provides value.

Strategic Outlook

Building on cases like this, Maritech’s vision is clear: to create a global ecosystem of specialist services that reinforces shipyard capabilities, secures owner confidence, and ensures that every vessel benefits from consistent standards of quality, supply, and warranty — wherever it docks.

48 Years of Excellence

MARITECH HELLAS Tribute at ICAP CRIF “Golden Anniversaries” business publication.

This feature article celebrates a significant milestone in our company’s journey. You are about to read about the foundational principles that have guided us for nearly five decades, our evolution from a local engineering firm to a global presence and our commitment to a sustainable and innovative future. It is a story of continuous growth, technical excellence and a steadfast focus on our core values.

MARITECH HELLAS was founded in Piraeus in 1977 by Anastasios Sorokas, with the goal of providing specialized solutions for critical marine subsystems. From its first steps, it established itself as an engineering company, with a commitment to reliability and well-documented technical support. Our philosophy is based on responsibility towards the client and a substantive understanding of the real requirements of each vessel.

Today, MARITECH is the technical and commercial hub of an international Group with a presence in Europe and Asia, maintaining the character of a flexible yet technically proficient unit. The company specializes in heat exchangers, desalination units, and next-generation spare parts—redesigned for increased durability, compatibility, and energy efficiency. It provides on-board technical support where required, repairs at fully equipped maintenance stations, and targeted retrofit upgrades, with end-to-end support from design to installation and testing.

Although the core of our activity remains shipping, MARITECH has extended its technical solutions to onshore industrial applications, energy projects and special offshore units. The same principles of technical consistency are applied in every environment—floating or fixed. MARITECH consistently serves fleets worldwide, with technical operations in ports, shipyards and floating installations. The scale of our global projects requires continuous quality assurance, field readiness and the application of defined technical protocols—regardless of the region or vessel type.

Since 2021, the “Green Series” program has been implemented, aiming to reduce waste, regenerate components and extend the lifecycle of critical systems. At the same time, the “ESG MARITECH 2030” plan aligns the company’s technical, supply, and commercial operations with clear indicators of sustainability, responsibility and governance.

MARITECH maintains a presence in R&D infrastructure in Singapore, internally strengthening knowledge, documentation, and innovation. Our technical choices are based on field experience and are adapted to the real needs of our clients.

Tripoleos 9a,

N. Ikonio, 18863 Perama

Phone: 2169005500

Follow us:

Anastasios Sorokas founded Sorokas Group, a company that provides specialized shipbuilding and engineering solutions in both Greece and Europe.

Dimitrios Sorokas renamed the company to Maritech Group. The Group specializes in plate heat exchangers and desalination units, providing customized spare parts, technical services and vertical support, both on-site and on-board.

Focusing on the global landscape, the Group transforms into Maritech Holding, headquartered in Hong Kong. At the same time, Maritech Global and an R&D center are established in Singapore, along with storage facilities in China, consistently aligning our moves with the “ESG MARITECH 2030” development plan.

GOLDEN ANNIVERSARIES 2025

113

Find the complete publication (in Greek) here

MARITECH’S STRATEGY FOR A RESILIENT AND INTELLIGENT MARITIME INDUSTRY

In a compelling interview with Forbes Greece, our CEO, Dimitrios Sorokas, sheds light on Maritech Group’s strategic vision for a maritime industry shaped by resilience and intelligence. Amidst global challenges, Maritech is redefining technical support with a preventive, locally focused, and smart approach. With strategic hubs in Europe and Asia, Maritech Group offers integrated, timely interventions.

Mr. Sorokas emphasizes that the future of maritime support lies in proactive, engineered solutions, particularly for critical thermal systems (PHE) that ensure vessel reliability and seamless operations. He also highlights the company’s commitment to applied sustainability, which is embodied in its MARITECH Green Series. This series is specifically designed for fewer failures and reduced waste, underscoring our dedication to tangible environmental benefits. Maritech Group is poised to lead the industry by ensuring continuity through precision and foresight.

Basic Life Support (BLS) & First Aid Seminar by Maritech Hellas

As part of our ongoing commitment to workplace safety and emergency preparedness, Maritech Hellas successfully organized a Basic Life Support (BLS) & First Aid Seminar, with a special focus on Cardiopulmonary Resuscitation (CPR) and choking response techniques.

Held at our facilities in N. Ikonio, Perama, the training was led by certified instructors and included:

Employees across departments actively participated in this hands-on session, gaining vital knowledge and confidence to act in critical situations — both onboard and onshore.

This initiative reflects the broader Maritech Group mission to foster a safety-first culture across all operations.

🙏 A sincere thank you to our team and trainers for supporting this essential cause.

🦺 Safety at Maritech is not just a policy — it’s a mindset.

Trusted by Public Utilities: Repeated Plate Heat Exchanger Refurbishment for National Power Plant

A leading national energy provider operating large-scale public power plants required specialized refurbishment of multiple plate heat exchanger (PHE) units used in its industrial cooling systems. As part of its scheduled maintenance strategy, the organization initiated a competitive public tender to secure a reliable, certified technical partner.

Challenge

• Time-sensitive repair windows during plant shutdown periods

• Heavy scaling, gasket degradation, and frame surface wear

• Need for full certification and quality documentation

• Strict compliance with public procurement and audit protocols

Our Solution

MARITECH was awarded the contract following a competitive tender process, based on our technical expertise, transparent QA/QC procedures, and proven ability to meet strict public-sector requirements.

We delivered a comprehensive refurbishment service for the PHE units, covering over 2,000 plates across multiple units. The project was completed in 20 working days, fully aligned with the client’s maintenance window.

Scope included:

• Disassembly and deep chemical cleaning of all plate packs

• Plate integrity checks and regasketing with OEM-compliant materials

• Frame reconditioning, including groove preparation and protective coating

• Hydrotesting and delivery of certification reports per unit

• QA/QC traceability and documentation to meet public audit standards

The Results

For over 8 years, MARITECH has been a trusted technical partner to the national energy provider, successfully delivering 6 refurbishment projects involving critical PHE infrastructure.

✅ Consistent on-time and certified delivery.

✅ Zero post-installation issues reported across all projects

✅ Full compliance with national procurement and audit standards

✅ Reinforced reputation as a reliable service partner for public infrastructure

Why Maritech

MARITECH combines deep technical knowledge with full independence from proprietary OEM systems — enabling clients to receive optimized service across a wide range of plate heat exchanger types and models. This multi-brand compatibility avoids vendor lock-in and allows for extended asset life, better cost control, and greater operational flexibility.

In addition, MARITECH applies a strict transparency protocol:

• Detailed inspection logs

• Pre/post condition documentation

• Certified test results

• Clear handover points and Owner’s Risk notifications where applicable

This structured approach gives clients enhanced visibility and confidence in every decision — supporting quality assurance, lifecycle planning, and long-term reliability.

Emergency ME LO Cooler Restoration

The root cause was traced to an internal failure of the Main Lube Oil Cooler. With no port access and a high risk of engine damage, a time-critical onboard solution was required for the container vessel with a capacity of 13,000 TEU, located at Shanghai Anchorage. During routine monitoring, the vessel’s crew identified oil residuals in the fresh water expansion tank and further noticed an increase in lube oil consumption.

Our Solution

MARITECH deployed a structured, lifecycle-oriented strategy across the client’s vessels:

• A flying team of senior MARITECH engineers was deployed and boarded the vessel at anchorage within 48 hours.

• Onboard diagnostics confirmed gasket failure and plate deformation inside the plate heat exchanger.

• As time did not allow external reconditioning, MARITECH coordinated the emergency use of the vessel’s stock plate pack, previously supplied under a preventive framework.

• The unit was reassembled and fully tested under controlled conditions, confirming full recovery of system integrity.

The Results

✅ Vessel resumed operations with no port call or delay.

✅ Engine shutdown was avoided, saving an estimated USD 45,000-60,000 in downtime and logistical costs.

✅ MARITECH’s predictive approach, combined with advance part readiness and onboard capability, ensured a fast, safe, and sustainable outcome.

Client Insight

Operators are adopting predictive and modular repair strategies to reduce risk and minimize downtime. This case illustrates the value of forward stocking and the ability to execute advanced service scopes on anchor. The successful outcome reflects a growing industry shift toward trusted partners like MARITECH, capable of executing critical repairs under pressure while maintaining the highest standards of quality, safety and sustainability.

From reactive repairs to strategic maintenance

A global fleet operator approached MARITECH after facing persistent issues across their vessels’ plate heat exchangers. Rising maintenance costs, reduced thermal efficiency, and frequent failures were disrupting operations. The fleet’s mix of OEM systems, irregular servicing, and absence of a preventive maintenance plan made the situation increasingly unsustainable.

Our Solution

MARITECH deployed a structured, lifecycle-oriented strategy across the client’s vessels:

• Fleetwide diagnostics to benchmark actual PHE condition and prioritize service needs

• Workshop reconditioning using our 10-step process: plate testing, proper re-gasketing, and pressure validation

• Cross-brand expertise applied to standardize quality across different OEMs

• Tailored preventive maintenance plan, including onboard crew routines, service tracking, and spare optimization

The Results

✅ 32% drop in annual PHE-related service costs

✅ 40% longer gasket life across high-temp units

✅ Zero unplanned shutdowns in 12 months

✅ Unified service methodology across fleet, for all units

Client Insight

“MARITECH brought structure and predictability into an area that was once chaotic. Their consistency across brands made a real difference.”

Maritech Group CEO, Dimitrios Sorokas, Interview on Capital.gr

We are pleased to share key insights from a recent interview given by Mr. Dimitris Sorokas, CEO of Maritech Group. On April 15, 2025, Mr. Sorokas had an insightful conversation with Capital.gr and journalist Mr. Giorgos S. Skordilis, emphasizing that in today’s volatile maritime industry, technical support is not merely an auxiliary service, but a critical pillar of reliability and operational continuity.

He highlighted Maritech Group’s strategic focus on anticipating needs, offering swift and intelligent responses to supply chain disruptions and geopolitical tensions, and investing in thermal management and desalination systems. The discussion also explored team expertise, predictive maintenance, global procurement flexibility, and the development of green technical support.

We extend our sincere thanks to Capital.gr and Mr. Skordilis for facilitating this discussion — capturing Maritech’s mindset of resilience, precision, and engineering intelligence in a changing world.

The client experienced persistent issues with a critical onboard plate heat exchanger. Despite prior attempts at cleaning and re-gasketing, the unit continued to underperform, failing pressure tests and affecting system stability.

Faced with a possible replacement scenario, the client sought an expert assessment from MARITECH.

Our Solution

MARITECH’s engineering team coordinated the safe transfer of the unit to our service center in Greece. Upon diagnostic inspection, we identified:

• Frame misalignment and signs of over-compression on several plates

• Non-standard gaskets that had deteriorated under marine operating conditions

• Incomplete fouling removal in key thermal zones

• Localized warping at plate edges affecting sealing performance

Our multi-step recovery process included :

• Flatness checks and alignment testing

• Targeted replacement of select plates (avoiding full plate pack replacement)

• Full mechanical and chemical cleaning of plates

• Re-gasketing using precision-selected gasket material, compound, and hardness for extended life in high-temp operation.

The Results

✅ PHE fully restored and reinstalled onboard

✅ Estimated €38,000 in replacement costs avoided

✅ Thermal and sealing performance validated during sea trials

✅ Client reassigned additional units for MARITECH support and lifecycle management

Client Feedback

“Clear communication, reliable outcome, no surprises. We’ve continued with MARITECH for similar units.”

In late December 2024, we were requested by a Turkish shipyard to efficiently overhaul 12 plate heat exchangers on a 7455 TEU containership, restore their functionality and ensure their optimal operational performance within a strict 14-day deadline.

Our 𝐒𝐞𝐫𝐯𝐢𝐜𝐞 𝐓𝐞𝐚𝐦 led the technical assessment and overhaul planning while maintaining clear cross-team communication to avoid any delays or oversights throughout the process.

𝐑𝐞𝐩𝐚𝐢𝐫 𝐒𝐜𝐨𝐩𝐞

• Comprehensive inspections to identify condition

• Disassembly of the units for thorough cleaning

• Replacement of gaskets and some plates to enhance efficiency and prevent future leaks

• Reassembly of each unit followed by functional testing to ensure operational performance

• Final quality inspections to verify adherence to industry standards

𝐂𝐨𝐧𝐜𝐥𝐮𝐬𝐢𝐨𝐧

• Unit Dismantling

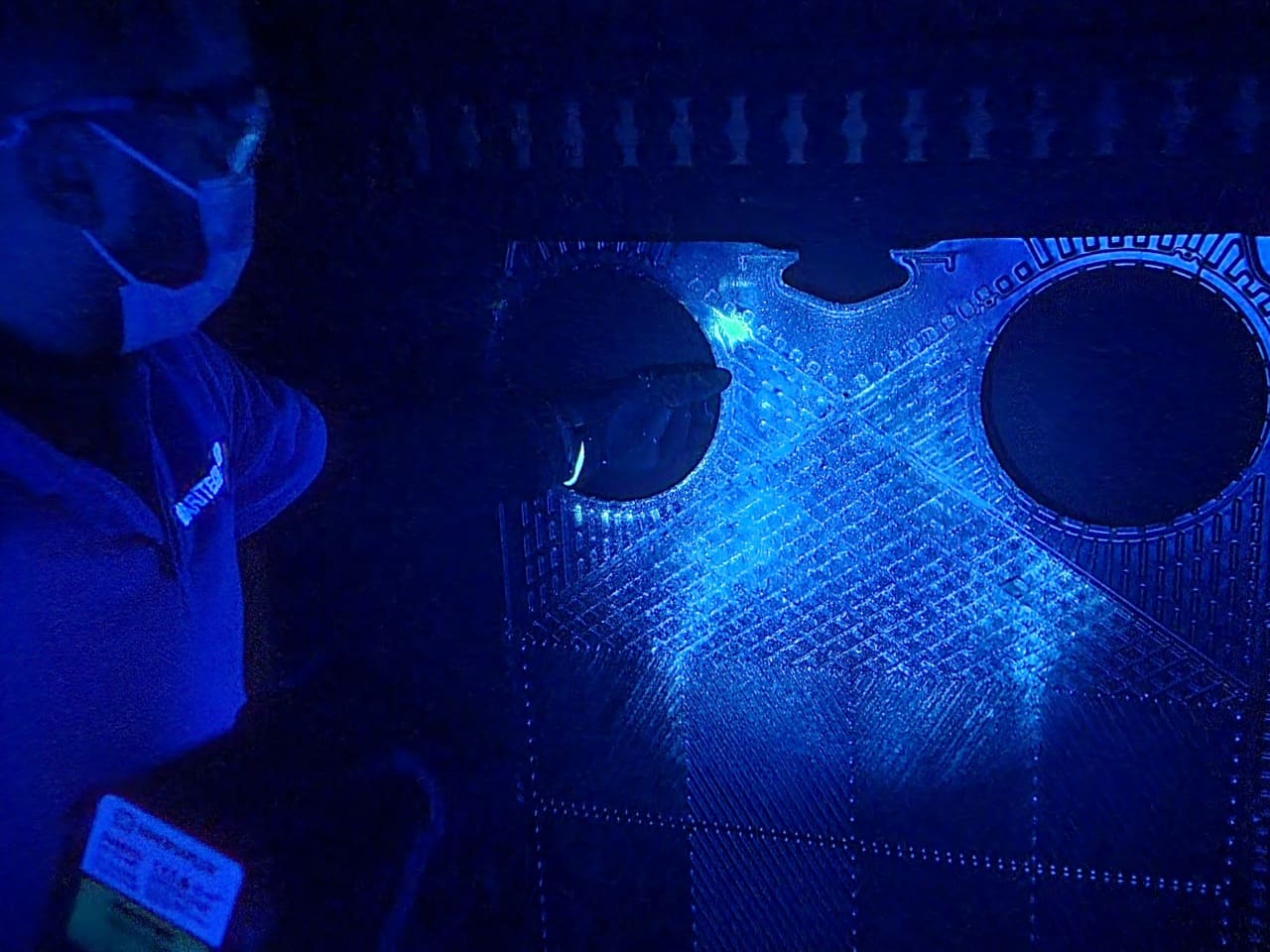

• Plate packs’ Inspection, Chemical Cleaning, UV Check, Re-gasketing

• Pressure Testing

• Operation/Troubleshooting Assistance

Outcome

Positive feedback from stakeholders highlighted the swift response and the successful completion of the project within the14-day time frame, underscoring our commitment to maintaining high operational standards and meeting tight deadlines.

We have recently delivered a turnkey plate pack renewal project for two (2) Plate Heat Exchanger units onsite a leading EU steel production plant.

Maritech studied the specifications of the old/existing equipment and consequently fabricated, installed and tested new plate packs with perfect fit and optimized thermal efficiency.

Work Scope:

• Dismantling of units

• Inspection and frame set restoration

• Fabrication of new plates

• Installation of plate packs

• Pressure Testing

The Challenge

Our Plate Heat Exchanger specialists fulfilled the plant’s safety requirements and successfully met the 48-hour predetermined timeframe by working in shifts around-the-clock.

Outcome

All works were completed successfully and results cross-checked by plant’s Quality Manager.

Maritech was requested to overhaul 2x Fresh Water Distillers units (with a capacity of 80m³/day each) on-board a 1.800 PAX passenger vessel, docked at a major Greek shipyard.

Our service team reviewed the equipment’s specifications along with the customer’s representative and yard’s project manager to determine the spare parts and works required to perform the commissioned task.

The Challenge

This specific project was exceptionally challenging since the subject vessel experienced production issues right after being built. On top of that, the installations of the specific machinery type are globally scarce, hence, limited spare parts were available.

Work Scope:

• Unit Dismantling

• Plate packs’ Inspection, Chemical Cleaning, UV Check, Re-gasketing

• Pressure Testing

• Operation/Troubleshooting Assistance

Outcome

All works were completed successfully, instructions were given to the crew and the results had been cross- checked by our customer’s and the shipyard’s representatives. This lady was ready to sail.

Maritech Hellas acquires the Great Place to Work® Certification for the 2nd consecutive year.

Piraeus, 4th July 2024

Maritech grows side-by-side with its people. We achieve our goals thanks to their persistent efforts and dedication, hence the least we can do is provide them a workplace that deviates from the standards and feels like home.

We proudly announce that our company has earned the Great Place to Work® Certification, a distinction that derives from the collective experience and the confidential evaluation of our team members.

Here’s a few numbers and facts regarding the certification’s reference period:

• Accidents: 0

• Very satisfied employees percentage: 96%

• Women in the workforce percentage: 32%

• Women in leader positions percentage: 29%

• Our employees engage in team building activities

• Our employees engage in voluntary activities

“We are committed towards our principles and our people to stay focused on our upward path and grant our personnel safety, satisfaction, development and fulfillment. Success results from collaboration and only together we can achieve our goals and reach even higher standards” – Plaka-Soroka Maria, Director, Maritech Hellas Ltd.

About Maritech

Maritech Hellas is a wholly owned subsidiary of Maritech Group Holding offering specialized repair services and spare parts for plate heat exchangers, fresh water generators and pumps for almost five decades. With a highly trained team, Maritech Hellas is the group’s flagship regarding technical operations, product design and research on new technologies and sustainable materials.

Marketing Team e-mail: marketing@maritechgroup.com

Read more at: www.greatplacetowork.gr

Maritech’stechnical expertise was requested from the operator of a 12-year-old superyacht regarding a damage issue on one of its MTU Diesel Generator sets. The engine had recently undergone routine overhaul, but while operating leakages occurred.

Work Scope:

• Dismantling of the whole unit and dispatch to our premises for inspection & cleaning

• Inspection & Chemical Cleaning

• UV Inspection

• Reassembly and Pressure Test

• Return on-board and Reinstallation

We were requested to overhaul all coolers of our customer’s 35K Chemical Tanker during her docking at Dubai Dry Docks World, with scope to remove/refit plate packs, renew gaskets and perform in situ press test for two Central Coolers, one Lub Oil and one M/E jacket.

Our team of service engineers attended the vessel while at S/Y and after the initial inspection was conducted, we discussed with our customers about the poor condition of the coolers, the overhauling options, we finalized the scope and timeline of the works.

Both Central Cooler frames were found with heavy pitting marks and Maritech was asked by the customers to coordinate with a local workshop for the machining of the frame sets and their correct re-installation onboard vessel.

After all the subject works completion and checkmark verification, Maritech engineers made a joint inspection with the vessel’s Superintendent and Chief Engineer and delivered all units in operation.

The specific project was most challenging and even though other workshops had turned it

down due to the poor condition of the coolers, it was completed successfully and within the given timeframe, enabling our customers to save substantial time and budget.

This is a blast from the past case that we wish to share with you.

Maritech’s Flying Team of Technicians attended our customer’s idled vessel in the middle of the North Pacific Ocean. The Main Engine’s Lube Oil Cooler suffered a total breakdown during voyage.

At the same time, our Land-based Team designed, assembled and shipped an emergency ME LO Cooler unit in order to be installed on-board.

Upon delivery, our technical experts installed and rigorously tested the unit, confirming its efficacy and good operation, verifying that the vessel was ready to safely sail.

Maritech Hellas is now a Great Place to Work® Certified Company

Piraeus, 2nd August 2023

Maritech Hellas proudly announces that it has acquired the Great Place to Work® Certification, after the meticulous and thorough evaluation process carried out by Great Place to Work® Hellas. This Certification is primarily an outcome of the direct, anonymous and confidential evaluation provided by the company’s employees regarding their daily experience in their work environment.

Maritech is not a typical employer, but a place where our people choose to dedicate their professional lives and build meaningful, rewarding careers with lasting relationships. They have the opportunity to grow and develop their skills while being encouraged to work and grow together. This is where they have a second home and a second family. Maritech is dedicated to ensuring that our employees have healthy, meaningful lives, which is why we emphasize on their holistic benefits. We believe in and empower honest work-life balance, and this is the reason why we earned our place in the Great Place to Work® family.

“Our mission is to offer world-class engineering solutions, create sustainable value and make the difference. We believe that an individual can have that impact, yet ongoing success requires a diverse team of qualified persons that cooperate closely and achieve significant results.” – Plaka-Soroka Maria, Director, Maritech Hellas Ltd.

About Maritech

Maritech Hellas is a wholly owned subsidiary of Maritech Group Holding offering specialized repair services and spare parts for plate heat exchangers, fresh water generators and pumps for almost five decades. With a highly trained team, Maritech Hellas is the group’s flagship regarding technical operations, product design and research on new technologies and sustainable materials.

Marketing Team e-mail: marketing@maritechgroup.com

Read more at: www.greatplacetowork.gr

Our customer, a world-leading corporation in breeding, growing and marketing of innovative plants requested an integrated proposition for their new establishment in the South East Europe.

After meticulously breaking down the request’s specifications, our R&D and Production experts vivified and successfully delivered a tailormade solution, meeting the customers’ expectations and the agricultural sector’s high standards.

Work Scope

Design, fabrication & commissioning of two Plate Heat Exchanger units.:

Industry: Power Supply

Scope: Energy Plant | PHE Maintenance

Maritech Group successfully delivered a repeated project for the Public Power Corporation SA.

It included the inspection, potential repairs and maintenance works regarding the Corporation’s facilities PHE units’ titanium plates.

Work Scope:

– Chemical cleaning of the plates

– Repair of rectifiable deformations

– UV checking and removal of defective plates

– Re-gasketing of all the received plate packs

– Assemblance & hydrotesting

When all was set and done, all products were dispatched and ready for operation at the Corporation’s energy plant.

We have the infrastructure and competency to successfully undertake such big scale projects on-time & within budget.

WE WERE REQUESTED TO CONDUCT IN-SITU INSPECTION, MAINTENANCE & UPGRADE WORKS ON OUR CUSTOMER’S 1700 DWT (1150 PAX) PASSENGER VESSEL’S ME LO AND LT FW COOLERS.

INSPECTION:

ME LO Coolers findings:

• Frame plate corroded at the SW inlet.

• Groove deformations on several plates due to excessive tightening.

• Wrong plate sequencing.

LT FW COOLERS findings:

• Plate packs had been excessively compressed and the majority of plates were found heavily deformed.

• Plate packs were found in poor condition, where the material aging was evident.

MAINTENANCE & REPAIRS:

ME LO COOLERS services:

• Frame inlet’s were reconditioned and machined.

• Frame sets were epoxy painted.

• Pressure plates were upgraded with filter sets and flanges.

• All plates were checked, cleaned, repaired from deformations and re-gasketed.

• Units were hydrotested at both circuits. No leakages were detected.

LT FW COOLERS services:

• Frame sets were machined, reconditioned and epoxy painted.

• Pressure plates were upgraded with filter sets and flanges.

• Rubber sleeves and bolts were renewed.

• All plates were checked, cleaned, repaired from deformations and re-gasketed.

• Units were hydrotested at both circuits. No leakages were detected.

RECOMMENDATIONS:

We advised our customers not to combine existing with new plates, and rather opt for the renewal option through acquiring and installing a complete plate pack. This way the can enjoy long-lasting, efficient performance results.

OUTCOME:

All units were delivered compressed and ready-for-installation.

Our customers’ lady was geared-up for her new voyages and ready to provide tons of joy to her future passengers.

WE WERE REQUESTED TO PERFORM PREVENTIVE IN-SITU MAINTENANCE WORKS ON VARIOUS GEA COOLERS TYPES, FOR OUR CUSTOMERS’ RO-RO VESSEL.

CONDITION MONITORING OF:

• 2 units of LT FW Coolers, consisted of 127pcs of titanium T0.5mm plates

• 2 units of Jacket HT Coolers, consisted of 92pcs of titanium T0.5mm plates

• 2 units of LO Coolers, consisted of 121pcs of AISI T0.5mm plates

WORK SCOPE:

• Plates’ Cleaning

• Repair of Deformations

• Re-gasketing

• Hydrotesting

• Re-assembling

SUGGESTIONS & UPGRADES:

• 2 units of LT FW Coolers, consisted of 127pcs of titanium T0.5mm plates, were upgraded to 141pcs. Additional plates were manufactured in our production facilities.

• 2 units of Jacket HT Coolers, consisted of 92pcs of titanium T0.5mm plates, were upgraded to 104pcs. Additional plates were manufactured in our production facilities.

• 2 units of LO Coolers, were both equally equipped with 121pcs of new AISI T0.5mm plates, also manufactured in our production facilities.

After pressure testing, our technical personnel re-installed units back on vessel and our client’s lady was ready to sail once more.

Safe seas and fair winds!

Maritech Group Technical Department

We were requested to perform an urgent maintenance service operation onboard our customers 5500 TEU lady berthed at Besiktas port, regarding one of her SONDEX S187 LT FW Coolers.

Our flying team of experts embarked the vessel, performed all necessary actions and proceeded with the inspection, cleaning, re-gasketing and replacement of the unit’s plates. Furthermore, we discovered that the subject unit’s frame set was heavily corroded, and subsequently moved forward with all necessary modification, installation and alignment actions. Upon all being set and done, we tested the unit and all leakage issues were successfully resolved. But this is not the conclusion of our story…

One of Maritech Group’ s core principles is being respectful towards our customers; act proactively, ensure their fleet’s seamless operations and, by extension, their best interest. Our team preemptively inspected the remaining couple of LT FW coolers and adjacent existent issues were unfolded. The second unit needed cleaning and re-gasketing works, while the third one’s status was diagnosed as “unrepairable”, thus a replacement with a new plate pack was deemed necessary.

Our findings and recommendations were evaluated as crucial and additional service actions are required to be done, in order to safeguard this lady’s seaworthiness.

Maritech Group Technical Department

Maritech Group Recycling Report

Feb. 21, 2023

Setting and fulfilling sustainable goals and substantially contributing to the resolution of the ongoing environmental challenges has become a priority of vital significance for all industries, and the maritime sector is no exclusion. Over the past decades tons of regulations have been enforced and major CSR initiatives have been adapted in the broader maritime cluster, making it a major – if not the leading – player in the global-scale battle against pollution.

Maritech Group has cultivated and adapted a philosophy of sustainability and proactiveness. We are implementing a circular operations approach in order to constantly deliver a positive environmental impact. We are glad to announce that our Recycling Program has been successful for another consecutive year.

Over 5.8 tons of scrap metal, production waste, obsolete and non-functional spare parts were gathered and recycled. At the same time we are persistently oriented towards further optimizing our fabrication, service and handling processes and contribute to the greater good.

Please be reminded that Maritech Group is a member of the Green Award Network and grants special incentives to all maritime companies participating in that great initiative.

Maritech Group expands its reach in Croatia and the Balkans

Jan. 16, 2023

We are excited to announce our new partnership focused on serving shipbuilding, retrofit yards, offshore and onshore industries in Croatia, Serbia, Slovenia and Montenegro regions

Maritech Group is a private and independent repair and production firm of specialists with solid experience in marine thermal equipment.

With more than 50 years of hands-on experience, the Group offers turnkey solutions , from the design of parts up to their commissioning and maintenance throughout the equipment’s’ lifetime circle, regardless their type and make.

“We work together with our partners to maximize localization projects towards a sustainable, diversified and increasing economic development”, Sorokas Dimitris, Group’s CEO.

With more than 500 repair projects each year, our goal is to maximize our global presence and support our customers on minimizing their asset downtimes with highly efficiently onsite, in-place repair works and flying teams, dedicated to plate heat exchangers and evaporators. Over the years, we have designed maintenance procedures & schemes that ensure precision and repeatability, placing our service level second to none.

Maritech Group Sales Department

sales@maritechgroup.com

Maritech Group joins Green Award Network

July 01, 2020

Maritech Group joins the Green Award Incentive Provider program by offering 7-10% discount on all its maintenance services to Green Award certified ships.

By being proactive and going beyond compliance with regulatory requirements, the shipping industry and its stakeholders substantially contribute to the general welfare and at the same time invest in sustainability. Acting preventatively is no simple task; hence responsible behaviors and actions must be acknowledged and rewarded in order for frontrunners to remain ahead of the game.

Green Award’s values, philosophy and work motivate all companies and institutions involved in shipping to engage in corporate social responsibility initiatives, beneficial to the common good. Maritech Group is proud to be part of the Green Award incentive provider network and have the opportunity to conduce to safe, environmentally responsible and sustainable shipping.

“We are glad to support the shipping community and social welfare through our membership in Green Award program” , said Dimitrios Sorokas, CEO.

Maritech Group offers Green Award certified vessels the following discounts for plate-type heat exchangers and fresh water generators:

– 7% on onboard maintenance services

– 10% on in-situ maintenance services.

About Maritech Group

Maritech Group manufactures and supplies high-quality alternative marine parts for critical machinery, provides specialized engineering services for plate heat exchangers and fresh water generators and commercially represents proven environmental technologies to the shipping industry.

About Green Award Foundation

Green Award certifies sea-going oil and chemical tankers, bulk carriers, LNG and LPG carriers, container carriers, offshore vessels, RoRo, inland navigation barges and river cruise vessels. Its assessment criteria cover environmental, quality and safety aspects, and performance of management and the crew. With this comprehensive approach and a diverse team of the industry’s experts supporting the scheme, Green Award secures the quality of its audits and real value of its certificate.

sales@maritechgroup.com

With nearly 150 ports and other maritime related organisations providing discounts to the certified companies and ships, the scheme motivates ship owners and managers to invest in the improvements on board and ashore and serves as a reliable Corporate Social Responsibility and risk reduction tool for participating shipping companies, ports and maritime service providers.

www.greenaward.org

At times of uncertainty, SOx Scrubbers are the most reasonable solution.

Feb. 26, 2020

Almost 2 months have passed since the implementation of IMO 2020 new fuel rules and the market is still surrounded by significant uncertainty. Choosing between installation of SOx scrubbers and changeover to compliant fuel has turned out to be a challenging puzzle, even for the most skilled of solvers.

With the HFO-VLSFO spread currently under $200, some owners have shifted towards the low-sulphur bunkers option. Yet, the majority of the industry is currently standby, waiting for the market to stabilize and recover from ongoing unforeseen circumstances. Bunker demand, and consequently VLSFO prices, are decreased due to the COVID-19 outbreak and the prolonged warm winter. Of course this situation is no normality and will probably not last after April/May period.

Moreover, serious concerns have risen regarding the quality of the new VLSFO that is reported to contain high-levels of aromatic compounds which result in an increase of black carbon emissions that pose a serious environmental threat, according to a study conducted by Finland and Germany and submitted to the IMO. Especially regarding the Arctic region, increased emitted black carbon volumes can create major negative environmental outcomes.

On the other hand, although some concerns have surfaced regarding the discharge of wastewater from open-loop systems, scrubbers remain a reliable IMO 2020 compliance option and at the same time a risk-mitigation factor, on both OPEX and environmental ends. We can take for granted that HFO prices will always be lower than VLSFO. Furthermore, according to Gibson shipbrokers, scrubber retrofitted vessels provide an approximate 30% reduction in black carbon emissions.

It is no coincidence that Maersk, whose stance was previously against Exhaust Gas Cleaning Systems, has strategically decided – and announced – to install SOx scrubbers on a large number of vessels and considerably increase the usage of HFO from 10% of total fleet consumption to 25% by the end of 2020.

It is said that uncertain times require certainty in decision making; if requested, Maritech Group is here to assist you.

Our principals, Pacific Green Marine Technologies (PGMT), offer the most cost-efficient SOx scrubber solution in the shipping industry, ENVI-Marine™, a system that effectively combines: maximum particulate absorption – thus comfortably meeting the required emission limits -, very low space and consumption requirements, a rectangular body with no moving parts that enables the advantageous non-enclosed installation option, and a very low cost. Most importantly, through joint venture with PowerChina, unrivalled access to shipyards and unlimited manufacturing capacity are achieved.

Maritech Group Sales Department

sales@maritechgroup.com

Maritech Group is the exclusive commercial agent of PGMT in Greece.

Maritech Group Enhances Manufacturing Capacity

Feb. 24, 2020

A scheduled investment in the upgrade and renewal of our production units has enabled the manufacturing of alternative pump parts for Fresh Water Generators at an increased capacity and range, while reducing time and overall cost.

All our production units are constantly supervised in order to assure that everything is in line with our quality standards and policy, placing Maritech Group in a unique position as the Real Alternative to OEM.

Our upgraded product line includes:

We invite and welcome your enquiries!

Maritech Group Sales Department

sales@maritechgroup.com

Maritech Group Recycling Report

Feb. 21, 2020

On 20.02.2020 we recycled over 4 tons of scrap metal and non-functional parts.

Sticking to our Green policy and philosophy, we constantly aim for a positive environmental footprint and substantial contribution to the local community’s welfare.